Shanghai SNOD Rubber Roller Manufacturing Co., Ltd.

Nuo QING ROLL MANUFACTURING (SHANGHAI) CO., LTD.

Address: No. 589 Fengyong Road, Qingcun Town Qinggang Industrial Park, Fengxian District, Shanghai

Zip code: 201414

Email: mail@shside.com.cn

Tel: +86-21-57569609

Fax: +86-21-57569659

Sales: +8613916373268

QQ: 2880099266

Accuracy of Rubber Roller Finishing Processing

Inspection items | Method of determination | Completion criteria |

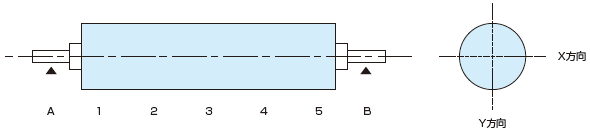

Outer Diameter of Rubber Roller | Measure 3-5 positions by micrometer or tape in the direction of plane length. The locations are determined according to the inspection category of specifications. The length of glue is measured at three locations below 500 mm, and the length of glue is measured at a point below 150 mm. | Less than 0-0.5mm |

Rubber roll cylindricity | The difference between the maximum value and the minimum value of the measured outer diameter. | Less than 0.05mm (rubber length less than 3000mm) Less than 0.07 mm (rubber length over 3000mm L/D25 below) |

Rubber roller hardness | A hardness tester is used to measure the hardness. | + 3 degrees |

True Roundness of Rubber Roller | The measurement difference of outer diameter at 90 degrees of the same circumference. | Less than 0.03mm |

Rubber roll runout | When grinding cots, the runout accuracy of metal part (A.B) is adjusted below 0.02mm to ensure the runout accuracy of cots surface. | Less than 0.05mm |

Medium and high shape [medium and high volume] [Outer diameter] | The outer diameter difference between the central part and the two ends is moderate to high. The central part was measured and the number of times was taken as the outer diameter size. | +0.05 mm (below 0.5 for medium and high volume) +0.1mm (above 0.5 for medium and high volume) 0-0.5mm |

Rubber Roller Surface (Rubber) Length | Measure the length of rubber and the lowest reading value by touching the surface of rubber roll parallel to the measuring ruler or tape. | 1 mm (face length less than 2000 mm) 2 mm (surface length over 2000 mm) |

※This value is the reference value of the general rubber material of our company.

Sponge material, sticky dust material, soft rubber material and soft polyurethane are not suitable for the above values.

The accuracy standard of COTS varies according to the industry and application. If individual inspection items require high accuracy, please consult with the company's business personnel.

For high precision iron core, the manufacturing value of COTS should also be consulted.